Electronics Manufacturing

Electronics manufacturing is the system of creating digital devices like phones, computers, and TVs. It involves designing, assembling, and checking out those devices to make certain they work correctly. This discipline performs a crucial function in our ordinary lives, as electronics manufacturing are everywhere, from our houses to workplaces.

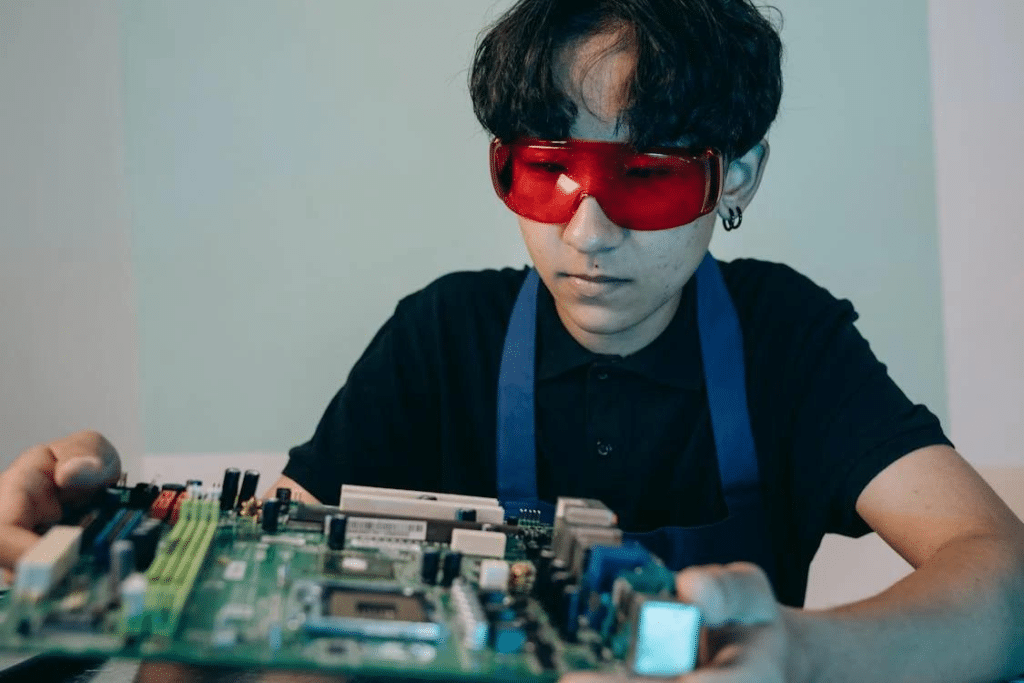

In electronics manufacturing, professional people use specialized tools and equipment to prepare the numerous components of digital gadgets. These components consist of circuits, chips, screens, and casings. Each element ought to be cautiously hooked up and linked to make certain the tool features properly.

Quality manipulation is important in electronics production to make certain that the gadgets meet excessive standards. Inspections and assessments are completed at distinct degrees of Electronics manufacturing to become aware of and fasten any defects. This enables us to assure that the very last merchandise is safe, reliable, and meets purchaser expectations.

Key Processes in Electronics Manufacturing

First, designers create plans for new digital devices. Next, people collect substances wished for production. Then, components are assembled in keeping with the layout specifications. Machines assist in putting additives correctly on circuit forums. After assembly, gadgets go through checking out for capability and safety. Quality manipulation tests make sure gadgets meet excessive requirements consistently. Faulty merchandise is diagnosed and corrected through inspection approaches.

Packaging is completed cautiously to shield completed digital merchandise. Shipping follows, with merchandise disbursed to stores or customers. Maintenance offerings can be supplied for digital gadgets post-purchase. Recycling projects assist in manipulating digital waste in greenways. Continuous development efforts refine production approaches for higher efficiency.

Components of Electronics Manufacturing

Components are small components used to make digital gadgets. Wires and cables join distinctive components of digital gadgets together. Circuit boards keep and join digital additives in gadgets. Chips and processors are like brains that manipulate gadgets` functions.

Screens show photographs and facts for customers to see. Casings shield inner components and deliver gadgets in their shape.

Batteries offer energy for digital gadgets to function properly. Sensors hit upon modifications inside the surroundings and cause responses. Antennas allow wireless conversation among gadgets and networks. Memory modules shop facts and facts for gadgets to access. LEDs emit mild and are utilized in shows and indicators. Connectors permit customers to plug in extra add-ons or peripherals.

Integration of Hot Runner Systems in Electronics Manufacturing

In electronics manufacturing, integrating hot runner systems, particularly in producing plastic components used in electronic devices, highlights a vital intersection of technologies. Hot runner systems streamline the injection molding process by ensuring consistent heat distribution throughout the mold, significantly reducing material wastage and enhancing the efficiency of production cycles. This technology is critical for creating high-precision parts such as plastic casings and components that house electronic circuits. Employing hot runner systems in the fabrication of these parts not only improves the overall product quality but aligns with sustainability goals by minimizing scrap. As the electronics industry continues to evolve, adopting such advanced manufacturing systems plays a crucial role in maintaining a competitive edge and meeting the rigorous standards of electronic device production.

Critical Electronic Components

Chips are tiny devices that manage digital gadgets` operations. Resistors modify the flow of power inside digital circuits. Capacitors save and launch electric power in digital gadgets. Transistors amplify or transfer digital alerts in circuits as needed. Diodes permit power to flow in the best direction. Inductors save power in magnetic fields and modify currents. Integrated circuits integrate a couple of capabilities right into a single chip.

Functional Roles in Device Assembly

Designers plan how components are shaped collectively for tool capability. Assemblers join additives consistent with layout and capability requirements. Testers take a look at if assembled gadgets paintings efficiently as intended. Inspectors make sure that every issue contributes to tool capability. Packers steadily assembled gadgets for safety at some point of transportation and storage. Distributors supply gadgets to shops or at once to customers. Users interact with gadgets to carry out favored features efficiently.

Quality Control in Electronics Manufacturing

Electronics Manufacturing Inspections confirm gadgets meet nice requirements at each production stage. Testing guarantees every tool’s capabilities efficiently earlier than leaving manufacturing facilities. Workers meticulously take a look at additives for defects and irregularities in the course of assembly. Machines resource in detecting faults with precision and accuracy. Standards manual nicely manages methods to keep consistency and reliability. Defective gadgets are identified, isolated, and corrected promptly.

Regular audits determine Electronics manufacturing processes for adherence to nice requirements. Feedback from clients informs upgrades to beautify the product nicely. Documentation information quality management measures for destiny reference and evaluation. Trained employees oversee well-managed processes to uphold requirements rigorously. Collaboration among departments guarantees seamless integration of well-managed measures. Continuous monitoring identifies regions for development in production processes.

Methods and Techniques of Quality Control

Inspections take a look at defects in digital gadgets in the course of production methods. Testing guarantees gadgets meet overall performance and protection requirements earlier than distribution. Statistical evaluation identifies developments and styles in production with nice data. Quality audits determine adherence to well-managed processes and requirements. Training applications teach people to manage strategies and processes nicely. Continuous development projects refine nice management techniques for higher efficiency.

Integration of Quality Control Across Manufacturing Processes

Quality management begins with factor inspection and maintenance via assembly. Testing happens at diverse levels to make sure a steady product is nice. Inspectors reveal every step to keep requirements throughout methods. Collaboration among departments guarantees seamless integration of nice measures. Feedback loops permit modifications to enhance niceness in the course of production. Documentation information nicely manages efforts to track and examine overall performance.

Technological Advancements in Electronics Manufacturing

Automation speeds up manufacturing approaches, growing production performance. Robotics help in duties like meetings and product handling. three-D printing permits fast prototyping and customization of digital parts. Machine getting to know improves fine management through detecting defects extra accurately. IoT allows real-time tracking and optimization of producing operations. Nanotechnology complements the overall performance and miniaturization of digital components.

Augmented truth aids employees in duties like preservation and troubleshooting. Blockchain guarantees traceability and transparency inside the delivery chain manner. Advanced sensors offer distinctive insights into production approaches for optimization. Additive production reduces waste and permits complicated geometries in manufacturing. Wireless charging generation eliminates the want for bodily connectors in devices. Cloud computing permits information storage, analysis, and collaboration for manufacturers.

Challenges and Opportunities

Market saturation demands profitability but fosters diversification and specialization. Escalating manufacturing costs necessitate performance enhancements for sustainable operations. Intellectual property protection is required with increased innovation and competition. Short product life cycles demand agile manufacturing and adaptive strategies. Cybersecurity threats require strong measures to protect sensitive information.

Future Trends

The same goes for manufacturing techniques so that it will be streamlined in phrases of overall performance through automation and AI. With sustainability practices turning into a greater integral, those are driven through the difficulty of environmentalism. 3-D printing will alternate the complete frontier of producing right into a shape of artistry with custom-designed and complicated designs. Robotics will take the price of all repetitive tasks, enhancing precision and productivity. IoT integration will allow even smarter, interconnected factories for optimized operations.

Quantum computing is likewise anticipated to alternate the manner statistics might be processed and optimized. Biodegradable electronics manufacturing will cope with issues from the surroundings with the aid of using inexperienced materials. Wearable electronics might be the following generation, merging invisibly into everyday life. Flexible electronics will allow innovative and adaptable device designs.

Augmented truth will enhance training, maintenance, and exceptional control methods. Digital twins will facilitate digital simulations for trying out and optimization. Collaboration and information sharing will pressure innovation in a connected industry.

Conclusion

Electronics manufacturing is a critical industry that shapes our contemporary world. From smartphones to computer systems and televisions, digital gadgets are ubiquitous in our day by day lives, highlighting the importance of this sector. Skilled workers, who use of specialized equipment and machinery, meticulously gather digital additives to make certain gadgets feature properly. Quality manipulation measures, consisting of inspections and trying out, ensure that merchandise meets excessive standards.

However, the enterprise faces demanding situations inclusive of growing manufacturing prices and cybersecurity threats. Despite those demanding situations, technological improvements like automation and AI provide possibilities for improved performance and innovation. As the enterprise keeps evolving, collaboration and model may be key to success. Looking ahead, destiny developments inclusive of sustainability practices and superior technology promise to similarly remodel electronics manufacturing, paving the manner for a greater related and sustainable destiny.

FAQs

What is the electronic manufacturing process?

The digital manufacturing method includes designing, assembling, and trying out digital gadgets. Skilled employees use specialized tools and equipment to make certain gadgets characteristics correctly.

What is electronics manufacturing and assembly?

Electronics manufacturing and meetings contain growing digital gadgets like telephones and computers. Skilled employees gather components to make purposeful products.

What kind of products does the electronic industry manufacture?

The electronics industry manufactures an extensive variety of products, including smartphones, computers, TVs, and appliances. These products enhance communication, entertainment, and productiveness in regular life.

What is electronics fabrication?

Electronics fabrication includes growing digital additives and elements via production processes. These additives are then used to gather diverse digital gadgets.