For residents of Fredericton relying on their fireplaces or wood stoves, winter preparedness is essential. However, not all chimney issues are visible throughout warmer seasons. This piece advises what to inspect for potential chimney repairs common in the region’s chimneys as the thermometer drops.

Chimney Inspection during Summer – The 1st Step

While winter draws the focus for many chimney owners, the best time for inspection and chimney repairs is actually during the warmer seasons. The varied temperature and weather conditions of fall and spring can expose weaknesses and the need for chimney repairs not evident at other times of year. Cracks may widen or mortar loosen under these stresses, highlighting trouble spots ripe for tuckpointing, repainting, or full liner replacement before colder exposure worsens the damage.

Catching repair needs early allows adequate time for high-quality chimney repairs to cure before demanding use begins with the next chill. An annual warm-weather evaluation protects chimneys from developing serious problems that could cause an unsafe or inefficient burning season.

Chimney Crown

The chimney crown is the topmost part of the chimney, made of concrete or masonry, that protects the chimney structure from rain, snow, and other elements. Over time, exposure to weather and temperature fluctuations can cause cracking or damage to the crown. An intact crown is crucial before winter arrives to prevent water from penetrating into the chimney structure.

Signs it’s time for a crown repair include large cracks, and missing or crumbling pieces of concrete. Water intrusion through the crown in the colder months risks freezing inside the chimney and expanding, which can weaken the chimney structure or cause cracks in the flue liner. Rebuilding or repairing a compromised crown ensures the chimney remains weather-resistant during winter. Masons can remove the old crown and re-lay it with a new concrete mixture. Epoxy or sealants may patch small cracks.

Mortar Repair

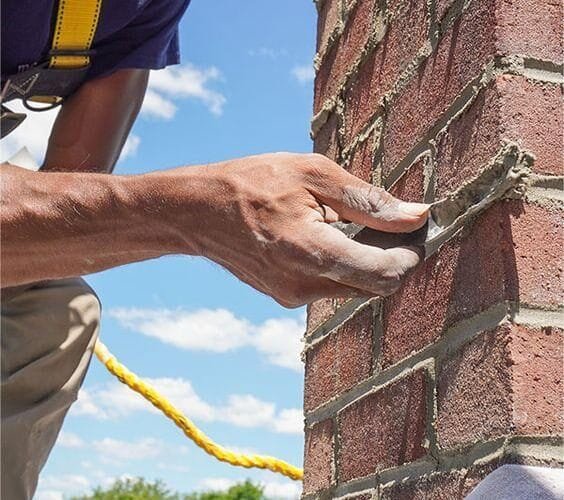

Mortar is the material used between bricks, stones or blocks of a chimney. Continuous exposure makes chimney mortar susceptible to deterioration over decades from rain, heat from fires, and freeze-thaw cycles. As mortar weathers away, it leaves gaps for water and air to enter the chimney. Tuckpointing involves scraping out loose mortar with hand tools and replacing it with new lime mortar matching the chimney’s original composition.

Proper tuckpointing restores the weather-resistant seal and supports the entire chimney structure. Crumbling, cracked or missing mortar can lead to structural instability problems if left unaddressed over the winter. Masons inspect for and replace all degraded mortar before the first cold snap arrives. Newly-tuckpointed mortar needs time to fully cure before a fire is lit, typically 4-6 weeks. Otherwise, an uncontrolled fire may cause a still-green chimney to crack or collapse from excess heat.

Flue Liner Repair or Replacement

The flue liner is the innermost layer of a masonry chimney, made of clay, ceramic, or stainless steel. It conducts smoke and combustion gasses up and out of the chimney while protecting the chimney structure from corrosion. Over time, the intense heat and chemicals in wood smoke take their toll on a liner. Cracks compromise safety and performance.

Before winter, the liner condition should be evaluated. Small cracks may be repaired with high-temperature sealant but severe damage necessitates replacement. A professional using special equipment can remove the old liner and install a new one. This involves sealing off the chimney so debris and irritants don’t spread indoors. A proper flue liner ensures safe, effective operation of the chimney, keeping users away from toxic smoke and reducing fire hazards during heating season.

Chimney Cap Installation or Repair

To prevent water infiltration and keep the chimney cavity clear, a mesh or solid cap covers the chimney opening. Over the years, caps have deteriorated from weather and need chimney repairs or full replacement. Before cold weather hits, evaluate a cap for integrity. Rusting, holes, or missing securing bolts mean water can enter and accumulate inside when temperatures drop. Ice or nesting materials may also obstruct the flow.

An intact cap is critical for proper drafting and safety. Blocked flues increase fire and carbon monoxide risks. A qualified technician can remove remnants of an old deteriorated cap and fit a new termination with securing screws out of reach of small children or wildlife. Various cap styles provide protection appropriate for your area’s climate and chimney design.

Firebox Inspection and Repair

The firebox is where fuel is burned within a fireplace or wood-burning stove. Subject to extremes of heat and cool, firebox brick or mortar can crack or collapse over time if it contains unaddressed damage. Before winter use, inspect for integrity with a light and mirror or camera. Pay attention to the back and sides which are difficult to examine regularly.

Any cracks or missing pieces of structure should be repaired to maintain safety and efficiency. Loose or damaged components if left could fall out during a fire, releasing sparks or ashes. A professional mason ensures any damaged areas are reinforced to contain combustion safely. Patched surfaces need time to fully cure before lighting seasonal fires. A sound firebox helps your appliance burn fuel completely and direct warmth indoors efficiently.

Damper Repair or Replacement

As the major control for airflow in a chimney, the damper plate inside directs smoke and gasses either up the flue or back down into the room. Old dampers often stick closed due to built-up creosote or break off rusty hinges with heavy use. Before each season, check if a damper opens and closes easily without smoke spillage.

A damper that does not close the flue fully when the appliance is not in use risks letting moisture or critters inside the chimney. Come winter, jostling or traffic may jar it loose posing a hazard. Stiff or damaged dampers should be repaired or replaced with one made of heat-treated steel and secured with serviceable hinges welded on. Properly functioning dampers help control the draft for steady, economical burns.

Flashing Repair or Replacement

Where a chimney penetrates a roof, metal flashing forms a waterproof seal. It channels rain and melting snow safely over shingles instead of at the flue. Flashing degrades gradually from freeze-thaw cycles and UV exposure. Before winter arrives, ensure yours does not leak with a visual inspection and integrity test such as splashing water.

Cracked or loose flashing risks damaging your home’s interiors or endangering indoor occupants with leaks during heavy storms. A flashing replacement involves removing old material, preparing the substrate, and securely attaching new corrosion-resistant flashings lapped in opposing directions. Small chimney repairs may only require re-caulking around nail heads. Overall waterproofing throughout roof penetrations like a chimney is key for peace of mind during winter weather.

Summary

Common chimney repairs before winter prepare your home’s fireplaces and wood stoves for safe, reliable warmth. Minor jobs now can prevent major structural damage or costly chimney repairs later from water intrusion at your most vulnerable outdoor joints and seams. For prompt protection year-round, routinely inspect and professionally maintain your chimney system annually in all seasons. Rely on a certified mason’s expertise to keep flues in their best condition.